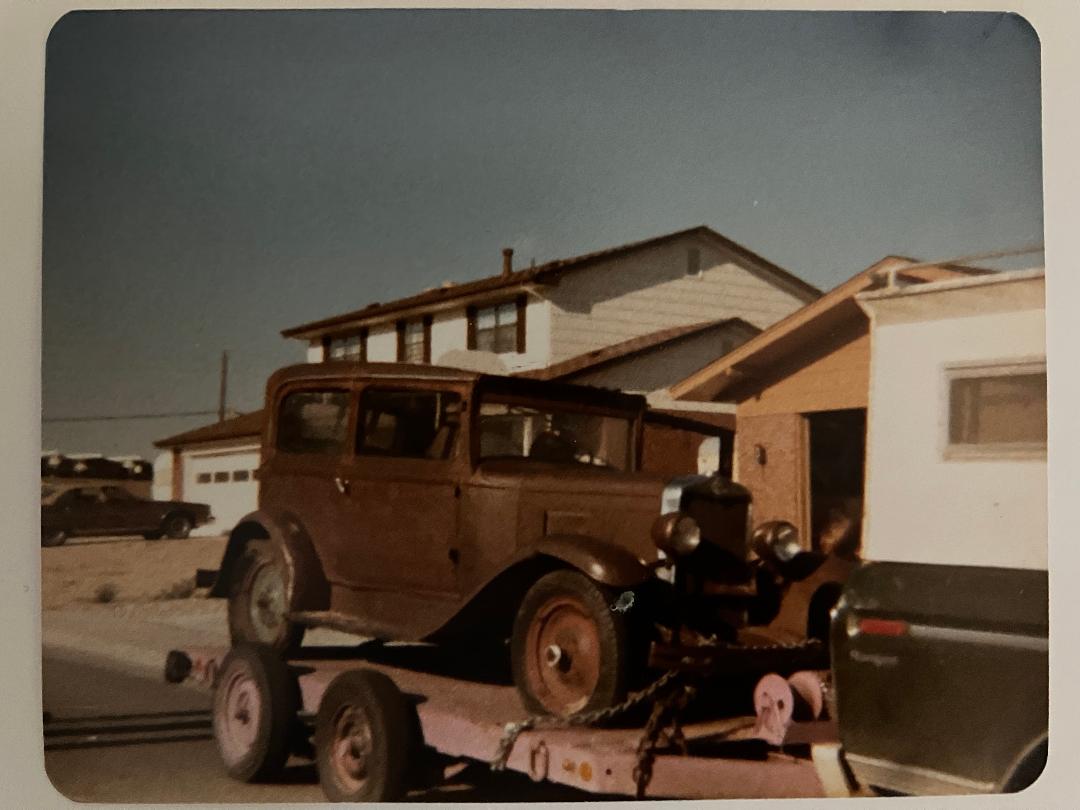

The year was 1976, I was 13 and for some unforeseen reason my father decided to do one of those infamous father-son projects. Early on a Saturday morning, we piled in the truck with the trailer in tow and headed to the small town of Akron in the eastern plains of Colorado. Later that morning, as we pulled onto a farm, there it sat with the rest of the long, run down farm equipment. Enter one 1930 Chevrolet two-door sedan, or as Chevrolet marketed it, the Chevrolet Coach, complete with a 194 CI, 50 HP, inline six-cylinder engine, and a 3-speed manual transmission. What a basket case.

The two front side windows were broken out. There wasn’t one spec of paint left on the car. The soft top had fallen inside the car. There was no upholstery left, and there was every bit of 8- to 12-inches of dirt on the floor. Most of the interior wood inside the body panels was rotted pretty badly. The big tear-drop front fenders were cracked so badly that 1-x ¼-inch thick metal straps had been bolted to the entire edge of the fenders in order to hold them together. The front bumper had been welded solid to the frame. We have to think that the fender repair, along with the welding of the front bumper, were most likely done because road conditions were fairly rough back in the ’30s.

For the next three years, the old girl went through an extensive, ground-up restoration. We started by pulling the body off of the frame, and my brother and I sanded every square inch of the frame with 3/8 electric drills and wire wheels. What a job, it seemed like it took forever. Once the undercarriage was cleaned and sanded it was all painted black. Then my dad and I replaced all of the interior wood with solid oak pieces.

The interior wood served two purposes, one, for securing the upholstery, and two, for attaching door hardware such as window mechanisms, door handles, and locks. Yes, a 1930 Chevy actually has roll down windows front and rear. The roof structure was made up of 2-inch wide by ¼-inch thick poplar wood strips that ran in two different directions; we made these pieces on an old bandsaw.

The car then headed off for paint. Most of the cracks and body work were done by an old timer that knew how to do lead body work. The body was painted dark blue, and the front and rear fenders were done in gloss black. The white pin striping following the main body line along with the hood louvers was done by hand, just like it had been done back in the day.

The engine was eventually rebuilt using the original babbitt bearing method. The upholstery was replicated to its original design by utilizing old photographs of other cars from that period. The wiring harness, along with the spark plug wires, had become victims of the farm mice. We made our own harness and spark plug wires with modern wire.

The most amazing thing of the entire ordeal was the fact that after that old car had sat for some 30 years, the engine turned over and fired right up after the fourth or fifth try. Man, they don’t build them like that anymore. That car was definitely a basket case and was my first experience with a restoration project.

By Chris Ochs